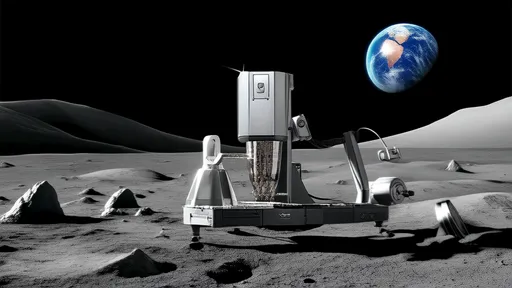

The concept of crafting ceramics on the Moon may sound like science

fiction, but recent advancements in material science and lunar

exploration have brought this idea closer to reality. Researchers are

now investigating the potential of using meteorite dust—a resource

abundantly available on the lunar surface—to create durable,

high-performance ceramics. This innovation could revolutionize

construction and manufacturing in space, offering a sustainable

solution for future lunar bases and beyond.

Unlike Earth, where ceramics are traditionally made from clay and

other minerals, the Moon lacks these conventional materials. However,

it is rich in regolith, a layer of loose, fragmented material covering

its surface. Within this regolith lies a significant component of

meteorite dust, a byproduct of billions of years of cosmic collisions.

Scientists believe this dust, when processed and fired under

controlled conditions, could yield ceramics with unique properties

suited for the harsh lunar environment.

The Science Behind Lunar Ceramics

The process of transforming meteorite dust into ceramics begins with

its composition. Lunar regolith contains silicates, oxides, and trace

metals—ingredients that, when heated, can fuse into a solid,

glass-like material. Early experiments conducted in simulated lunar

conditions have shown promising results. By subjecting compressed

regolith samples to high temperatures, researchers have produced small

ceramic tiles that exhibit remarkable strength and thermal resistance.

One of the key challenges lies in replicating the firing process

without the abundant oxygen and atmospheric pressure found on Earth.

Traditional kilns rely on these conditions, but lunar ceramics would

require innovative approaches, such as solar sintering or microwave

heating. These methods could harness the Moon’s natural resources,

like sunlight, to achieve the necessary temperatures for ceramic

formation.

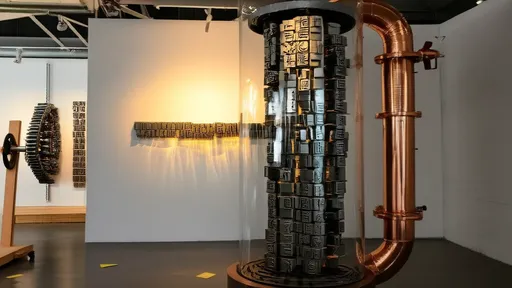

Applications in Lunar Infrastructure

The ability to manufacture ceramics on the Moon opens doors to

numerous practical applications. One of the most immediate uses would

be in construction. Lunar ceramics could serve as building blocks for

habitats, radiation shields, and even landing pads. Their high melting

point and resistance to micrometeorite impacts make them ideal for

protecting structures and equipment from the Moon’s extreme

conditions.

Beyond construction, space ceramics could play a vital role in tool

and component manufacturing. Instead of transporting heavy machinery

and materials from Earth, future lunar settlers could rely on locally

sourced ceramics to produce everything from laboratory equipment to

mechanical parts. This self-sufficiency would drastically reduce the

cost and logistical challenges of sustained lunar missions.

Challenges and Future Prospects

Despite the excitement surrounding lunar ceramics, significant hurdles

remain. The lack of water, a critical component in traditional

clay-based ceramics, necessitates alternative binding agents.

Researchers are exploring organic compounds or even lunar-derived

materials to act as adhesives during the forming process.

Additionally, the long-term effects of lunar gravity on ceramic

durability are still unknown, requiring further study.

Looking ahead, collaborations between space agencies and private

enterprises could accelerate the development of this technology.

NASA’s Artemis program and initiatives by companies like SpaceX aim to

establish a human presence on the Moon within the next decade. If

successful, lunar ceramics could become a cornerstone of off-world

industry, paving the way for similar innovations on Mars and other

celestial bodies.

The journey from meteorite dust to functional ceramics is a testament

to human ingenuity. As we venture further into space, the ability to

harness local resources will be paramount. Lunar ceramics represent

not just a scientific breakthrough, but a step toward a future where

humanity thrives beyond Earth.