In the ever-evolving landscape of renewable energy, a surprising

collaborator has emerged from the natural world: the humble silkworm.

Researchers are now harnessing the intricate artistry of these insects

to develop a new generation of solar cells, blending ancient

biological craftsmanship with cutting-edge photovoltaics. The result?

A fascinating synergy between insect engineering and sustainable

energy that could redefine how we think about solar technology.

The concept revolves around silk fibroin, a protein produced by

silkworms to spin their iconic cocoons. This remarkable material

possesses unique optical and structural properties that make it an

unexpectedly ideal candidate for solar cell applications. When

processed into ultrathin films, silk fibroin demonstrates exceptional

light-management capabilities, allowing photovoltaic materials beneath

it to capture sunlight more efficiently. What nature perfected over

millions of years of evolution is now being adapted to address one of

humanity's most pressing challenges.

Traditional solar panels, while effective, often

suffer from limitations in flexibility, weight, and environmental

impact during manufacturing. The incorporation of silk-based materials

offers solutions to these very issues. Silk fibroin films are not only

biodegradable and biocompatible but also incredibly lightweight and

flexible. This opens up possibilities for solar applications where

conventional rigid panels would be impractical - from wearable energy

harvesters to building-integrated photovoltaics that blend seamlessly

with architectural designs.

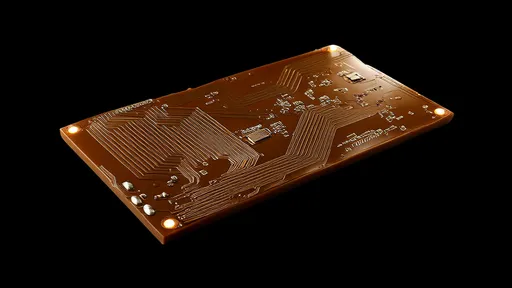

The production process begins with carefully harvesting silk cocoons

and extracting the fibroin proteins. Through a series of purification

and processing steps, researchers create transparent films thinner

than a human hair yet remarkably durable. These films can then be

combined with various photovoltaic materials, including organic

polymers and perovskite crystals. The silk layers serve multiple

functions: enhancing light absorption, protecting delicate solar

materials, and even improving the structural integrity of the entire

device.

Perhaps most intriguing is how the silk proteins

self-assemble into nanostructures that manipulate light in beneficial

ways. The natural molecular arrangement of fibroin creates microscopic

patterns that scatter incoming sunlight, increasing the path length of

photons within the solar cell and boosting energy conversion

efficiency. This biological photonic architecture, refined through

evolution, outperforms many artificially engineered light-trapping

structures in both performance and manufacturing simplicity.

Early prototypes have demonstrated promising results, with

silk-enhanced solar cells achieving comparable efficiency to

conventional designs while offering additional advantages. The

biodegradable nature of silk components means these devices could

significantly reduce electronic waste in the renewable energy sector.

Moreover, the low-temperature processing required for silk-based

photovoltaics translates to lower energy consumption during

manufacturing, further enhancing their environmental credentials.

The research extends beyond just using silk as a passive component.

Scientists are exploring ways to genetically modify silkworms to

produce fibroin proteins with tailored properties optimized for solar

applications. By adjusting the amino acid sequences, they aim to

create silk varieties with enhanced light absorption characteristics

or improved compatibility with specific photovoltaic materials. This

bioengineering approach could lead to a new era of "designer silk"

specifically grown for energy technologies.

Architectural integration represents one of the most

exciting potential applications. Imagine office buildings clad in

shimmering, silk-incorporated solar windows that generate power while

maintaining transparency. Or consider disaster relief scenarios where

lightweight, rollable solar mats could be rapidly deployed. The

aesthetic possibilities are equally compelling - silk's natural

iridescence could allow solar installations to become design features

rather than utilitarian additions.

Challenges remain, of course. Scaling up production while maintaining

the precise material properties requires careful optimization. The

long-term durability of organic materials in outdoor conditions needs

further testing. And researchers continue to work on improving the

efficiency of silk-based photovoltaics to compete with conventional

silicon cells. Yet the progress made so far suggests these hurdles are

not insurmountable.

This innovative approach represents more than just a technical

advancement. It symbolizes a philosophical shift in how we might

develop future technologies - not by fighting against nature, but by

learning from and collaborating with it. The silkworm, an insect

humans have cultivated for millennia for its luxurious fibers, may now

contribute to solving one of our most modern dilemmas. In this

intersection of entomology and energy science, we find a poetic

reminder that solutions to tomorrow's problems might be hidden in

plain sight, woven delicately in nature's timeless designs.

As research continues, the potential applications multiply. Medical

devices could incorporate tiny silk solar cells to power implants.

Remote sensors might run indefinitely using biodegradable energy

harvesters. Even space applications are being considered, where the

combination of lightweight properties and radiation resistance could

prove valuable. The marriage of this ancient biological material with

futuristic energy technology continues to surprise even its developers

with new possibilities.

The story of silk solar cells serves as an inspiring example of

biomimicry at its finest. It demonstrates how looking to nature's

solutions - developed and refined over evolutionary timescales - can

provide elegant answers to contemporary engineering challenges. As we

stand at the crossroads of ecological crisis and technological

advancement, such harmonious collaborations between biology and

engineering may light the way forward, quite literally, toward a more

sustainable future.