The concept of turning wastewater into a valuable resource has long

been a dream of environmental scientists and sustainability advocates.

Now, with the emergence of algae-based protein factories, that vision

is becoming a reality. These innovative facilities are harnessing the

nutrient-rich properties of wastewater to cultivate algae,

transforming what was once considered a waste product into a highly

nutritious and sustainable protein source.

Algae: The Unsung Hero of Sustainable Nutrition

Algae, often overlooked in discussions about alternative protein, is

proving to be one of the most efficient and environmentally friendly

sources of nutrition available. Unlike traditional livestock farming,

which requires vast amounts of land, water, and feed, algae can be

grown in compact spaces using minimal resources. What makes this even

more remarkable is that algae thrive in wastewater, absorbing excess

nutrients like nitrogen and phosphorus that would otherwise contribute

to water pollution.

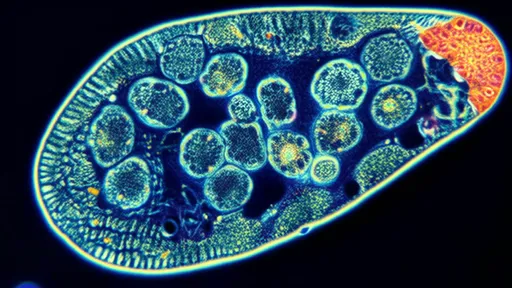

The process begins with the careful selection of algal strains that

are particularly efficient at converting wastewater nutrients into

biomass. These strains are then cultivated in controlled environments

where sunlight, temperature, and nutrient levels are optimized for

growth. The result is a rapid multiplication of algae that can be

harvested within days, a stark contrast to the months or years

required for traditional livestock to reach maturity.

From Wastewater to Superfood

The transformation from wastewater inhabitant to superfood involves

several crucial steps. After harvesting, the algae undergo a thorough

cleaning process to remove any remaining contaminants. The biomass is

then processed to extract its valuable components, including proteins,

omega-3 fatty acids, and various micronutrients. The final product can

take many forms, from protein powders and nutritional supplements to

whole food ingredients that can be incorporated into a variety of

dishes.

What sets algae protein apart is its impressive nutritional profile.

Many algal species contain all nine essential amino acids, making them

a complete protein source comparable to animal products. Additionally,

they're rich in antioxidants, vitamins, and minerals, offering health

benefits that extend far beyond basic nutrition. For populations

struggling with malnutrition or limited access to diverse food

sources, algae protein could be a game-changer.

The Environmental Advantage

The environmental benefits of wastewater-grown algae protein are

substantial. Traditional wastewater treatment plants consume

significant amounts of energy to remove nutrients before releasing

water back into the environment. Algae cultivation accomplishes this

nutrient removal naturally while simultaneously producing valuable

biomass. This dual-purpose approach represents a circular economy

solution that could revolutionize both water treatment and food

production systems.

Moreover, algae cultivation has a remarkably low carbon footprint

compared to conventional protein sources. The plants absorb carbon

dioxide as they grow, helping to mitigate greenhouse gas emissions.

When considering the full lifecycle - from cultivation to processing -

algae protein production emits a fraction of the greenhouse gases

associated with livestock farming while using substantially less water

and land.

Overcoming Challenges and Scaling Up

While the potential is enormous, scaling up algae protein production

from wastewater isn't without its challenges. One major hurdle is

developing cost-effective harvesting methods, as separating algae from

water can be energy-intensive. Researchers are exploring various

techniques, from advanced filtration systems to innovative

flocculation methods that cause algae to clump together for easier

collection.

Another challenge lies in public perception. Despite its nutritional

benefits, algae protein still faces some consumer skepticism,

particularly in Western markets where it's less familiar than

plant-based alternatives like soy or pea protein. Education and

creative product development will be key to overcoming these barriers

and establishing algae as a mainstream protein source.

The Future of Food and Water Treatment

As the technology matures, we're beginning to see the first

commercial-scale algae protein facilities emerge. These pioneering

operations are demonstrating that the concept works not just in the

lab, but in real-world conditions at meaningful scales. Some

facilities are even designed as modular systems that can be

implemented at existing wastewater treatment plants, creating new

revenue streams for municipalities while improving environmental

outcomes.

Looking ahead, the integration of algae protein production with

wastewater treatment could become standard practice in sustainable

city planning. Imagine urban areas where every wastewater treatment

facility doubles as a food production center, contributing to local

food security while cleaning water and reducing emissions. This vision

of a truly circular food system may be closer to reality than we

think, thanks to the humble yet extraordinary algae.

The implications extend beyond just human nutrition. Algae biomass

from these systems could also be used as sustainable feed for

aquaculture and livestock, potentially reducing pressure on wild fish

stocks and deforestation for animal feed crops. The versatility of

algae as a resource makes it a cornerstone of what could become a more

sustainable and efficient global food system.

As research continues and technology improves, the efficiency of these

systems will only increase. Scientists are working on optimizing algal

strains for both nutrient uptake and protein content, while engineers

refine cultivation systems to maximize productivity. The coming years

will likely see significant advancements that make algae protein from

wastewater an increasingly viable and attractive option for feeding

our growing population sustainably.