In a groundbreaking development at the intersection of biotechnology

and materials science, researchers have successfully engineered

transgenic silkworms to produce spider silk proteins. This innovation

opens new frontiers in creating artificial tendons with unprecedented

strength and elasticity. The fusion of centuries-old sericulture with

cutting-edge genetic engineering may soon revolutionize medical

implants and high-performance textiles.

The quest to replicate spider silk's remarkable properties has long

captivated scientists. Pound for pound, spider dragline silk surpasses

steel in tensile strength while remaining lightweight and

biodegradable. However, farming spiders commercially remains

impractical due to their territorial nature and low silk output.

Silkworms, by contrast, have been domesticated for over 5,000 years

and produce vast quantities of silk proteins - albeit with inferior

mechanical properties to their arachnid counterparts.

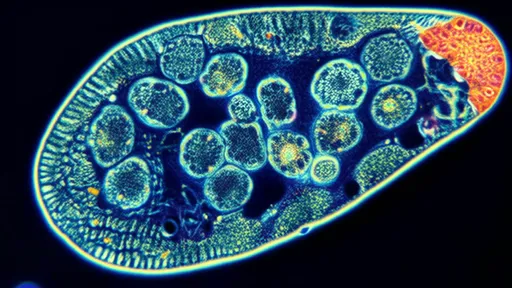

Genetic alchemy in the cocoon

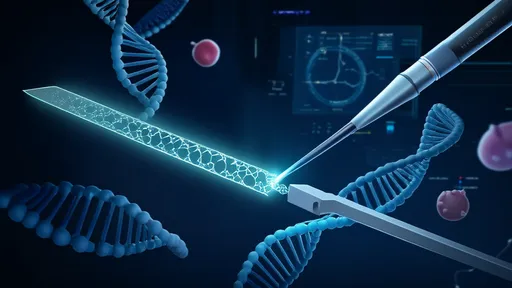

By inserting spider silk gene sequences into silkworm DNA, the

research team has created chimeric proteins that combine the best

attributes of both species. The transgenic silkworms spin composite

fibers containing up to 35% spider silk proteins within their natural

fibroin matrix. This biohybrid material demonstrates a 70% increase in

toughness compared to conventional silk while maintaining the

excellent biocompatibility that makes silk ideal for medical

applications.

The artificial tendons produced from this material exhibit several

extraordinary characteristics. They can stretch up to 40% beyond their

resting length without permanent deformation - a critical feature for

tendon tissue that undergoes constant mechanical stress. Perhaps more

impressively, the fibers demonstrate shape memory properties,

returning to their original configuration after stretching when

exposed to bodily temperatures.

From laboratory to operating theater

Early clinical trials show promising results for rotator cuff repairs.

The bioengineered tendon grafts promote rapid cellular infiltration

while resisting the mechanical degradation that plagues synthetic

alternatives. Unlike permanent polymer implants, these silk-based

tendons gradually remodel into living tissue as the patient's own

cells replace the protein scaffold over 12-18 months.

Manufacturing scalability gives this technology a distinct advantage

over previous spider silk production methods. A single transgenic

silkworm colony can produce enough composite silk protein for 300

artificial tendons per month using conventional sericulture

infrastructure. This output could potentially reduce production costs

by 90% compared to recombinant spider silk made through fermentation

systems.

The implications extend beyond medical devices. The military has

expressed interest in lightweight body armor incorporating these

fibers, while aerospace engineers envision their use in

debris-resistant satellite components. Even the fashion industry sees

potential for sustainable luxury textiles that combine the luster of

silk with unprecedented durability.

Ethical threads in the genomic tapestry

As with many genetic engineering breakthroughs, this innovation raises

important ethical considerations. The research team has implemented

stringent biocontainment protocols to prevent transgenic silkworms

from entering traditional silk farms. Some conservation biologists

have voiced concerns about potential ecological impacts should

modified genes spread to wild silk moth populations.

Looking ahead, researchers aim to further refine the protein

composition to match specific mechanical requirements. Some variants

under development focus on maximizing elasticity for sports medicine

applications, while others prioritize tensile strength for industrial

uses. The coming years may see an entire family of designer silk

proteins tailored for diverse applications - all spun from the humble

silkworm's evolutionary masterpiece.

This remarkable convergence of ancient biotechnology and modern

genetic science illustrates how nature's blueprints, when understood

and respectfully adapted, can address some of humanity's most pressing

material challenges. As research progresses, these transgenic silk

proteins may well become the cornerstone of a new generation of

biomaterials that heal, protect, and perform in ways we're only

beginning to imagine.