The shipping industry has long been plagued by the enormous fuel costs

associated with vessel operation. With global trade relying heavily on

maritime transport, even minor improvements in fuel efficiency can

translate into significant financial and environmental benefits. One

of the most promising innovations in this field is the application of

shark-inspired micro-riblet coatings on cargo ships—a technology that

reduces hydrodynamic drag and slashes fuel consumption.

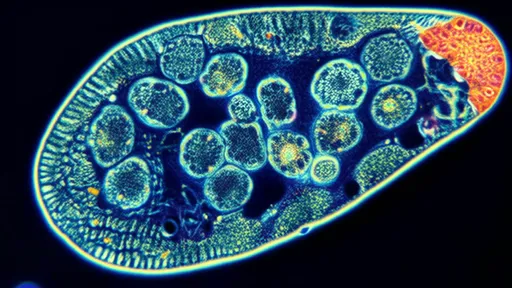

Sharks, as apex predators of the ocean, have evolved over millions of

years to move through water with minimal resistance. Their skin is

covered with tiny, tooth-like structures called dermal denticles,

which are arranged in a pattern that disrupts turbulent flow along

their bodies. Engineers and marine biologists have studied this

phenomenon, leading to the development of synthetic riblet films that

mimic this natural design. When applied to the hulls of cargo ships,

these micro-grooved surfaces can reduce drag by as much as 5-10%, a

seemingly modest figure that nonetheless yields massive savings over

time.

The science behind riblet technology is rooted in fluid dynamics. As

water flows over a smooth surface, it creates turbulence, increasing

drag and forcing ships to expend more energy to maintain speed.

Riblets work by altering the boundary layer of water molecules closest

to the hull. The microscopic grooves channel the flow in a way that

reduces eddies and vortices, effectively smoothing the passage of the

vessel through the water. This principle has been tested extensively

in wind tunnels and water tanks before being adapted for commercial

shipping.

Several major shipping companies have already begun retrofitting their

fleets with riblet coatings. One notable case involved a Panamax

container ship that underwent a full hull application of riblet film

during dry docking. Over the course of a year, the vessel reported an

8% reduction in fuel consumption, amounting to savings of nearly

$400,000 annually. Given that fuel accounts for roughly half of a

ship’s operating costs, the return on investment for such

modifications is compelling. The coating itself, typically made from

durable polymers or advanced composites, can last for several years

before requiring replacement.

Beyond economic advantages, the environmental impact of riblet

technology cannot be overstated. The International Maritime

Organization (IMO) has set ambitious targets to cut greenhouse gas

emissions from shipping by at least 50% by 2050. Since drag reduction

directly correlates with lower fuel burn, widespread adoption of

shark-skin coatings could play a pivotal role in meeting these goals.

Fewer emissions mean not only reduced carbon footprints but also

decreased output of sulfur oxides and particulate matter, which are

harmful to marine ecosystems and human health.

Despite its promise, the technology is not without challenges.

Applying riblet films to large vessels is a labor-intensive process

that demands precision. The grooves must be aligned perfectly with the

direction of water flow to function effectively, and any damage or

fouling from marine organisms can diminish their performance.

Researchers are now exploring self-cleaning and anti-fouling variants

of riblet coatings to address these issues. Additionally, some

skeptics argue that the gains from riblets may be offset by the costs

of application and maintenance, though long-term data suggests

otherwise.

Looking ahead, the integration of riblet technology with other

fuel-saving measures—such as air lubrication systems or advanced

propeller designs—could further enhance efficiency. As computational

modeling and material science continue to advance, future iterations

of these coatings may offer even greater drag reduction. What began as

an observation of nature’s ingenuity has now evolved into a

transformative tool for sustainable shipping. The oceans’ most

efficient swimmers have, quite literally, shown the way forward.